Gain precious time with a turnkey solution for teaching the fundamentals of industrial mechanics

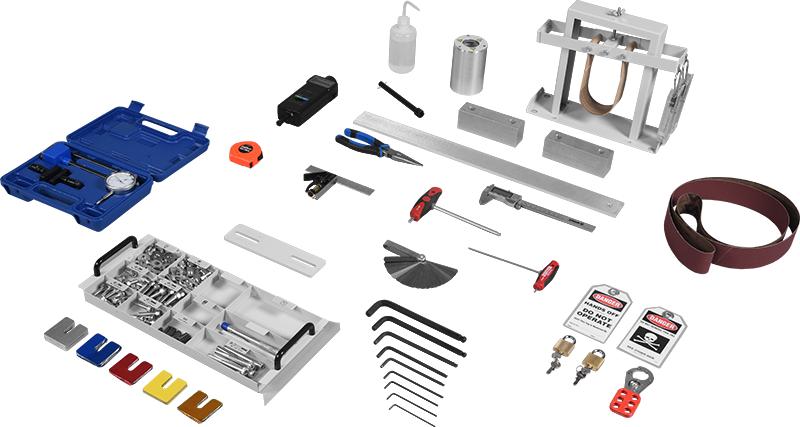

This package includes the Workstation and components common to most experiments such as shafts, couplings, pillow block bearings, fasteners and tools. A three-phase motor, an adjustable-height motor mounting base and a Prony brake are also included.

Versatile and equipped with movable T-slotted extrusions, the Workstation is at the heart of the Mechanical Drives Learning system. Students use it to quickly assemble a variety of mechanical drive set-ups. They can also test the set-ups with the included variable frequency drive and Prony brake to control the motor speed and load, creating various usage scenarios.

This ergonomic workstation is designed to minimize assembly time. Positioning the T-slotted extrusions and the main components, such as the motor and pillow block bearings, only requires a single tool and a couple of minutes, allowing students to focus their attention on the most relevant learning objectives.

Safety is maintained with an industrial-grade detection circuit that cuts power when the polycarbonate cover is opened. Trainees are asked to perform a lockout/tag out procedure on the main switch to prevent accidental activation of the motor while they are working. The cover can also be locked when closed to further improve safety during operation and allow instructors to control access to the components.

The Workstation is small enough to fit on most shop tables. Alternatively, an optional work bench is available with enough storage to accommodate most of the hardware of the entire Mechanical drives learning system.