TP 101: Pneumatics Basic Level

5407-1Gallery

Description

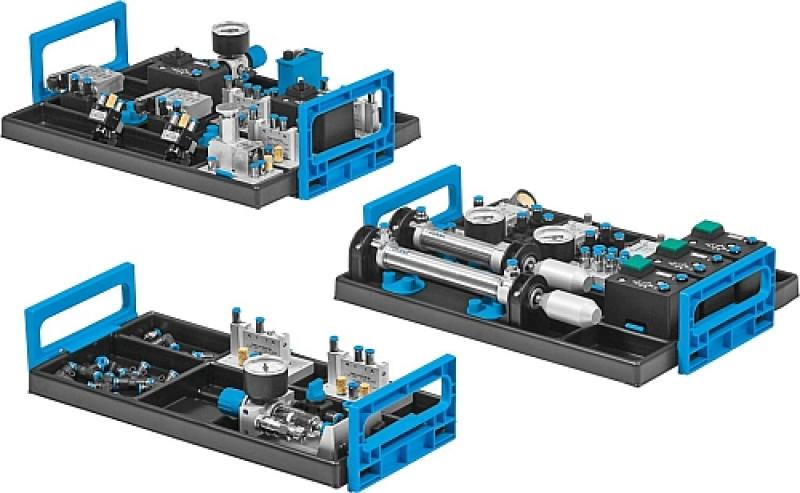

This training package includes all the components required for training in the fundamentals of pneumatic control technology. Components have the patented Quick Fix mounting system, pneumatic connections on the easily-accessible upper side of the components, and Quick Star fittings for plastic tubing PUN 4 x 0.75 mm with standard inside or outside diameters. All components are industrial quality.

Supplied in Systainer-compatible equipment trays, also suitable for workstation drawers. The scope of delivery includes adhesive symbols for clearly labelling where the components are kept.

Further enhanced and updated through the lessons learned from over 1,000 seminars on pneumatics.

- With brand-new industrial components, enabling you to teach tomorrow's industrial standard today.

- The workbook contains a series of graduated project exercises based on actual industrial applications, an enhanced section on fundamentals and a multimedia USB-Stick or download access.

- The number and design of the components are specially tailored to the projects contained in the workbook so that the main fundamentals can be imparted with little outlay.

Performance through close proximity

Switches and valves should be mounted as close to the actuator as possible for optimum performance. You can now apply the same principle when designing your circuits thanks to the new components. Furthermore, this approach also provides you with an easy way of demonstrating the performance of a one-way flow control valve. You can even record the measured values and analyse the results, for example using the TP 210

The next generation of valves

The new generation of valves allows the operation of various pressure zones – so nothing stands in the way of an efficient use of energy. In addition, the position of connection was optimised so that differences between the circuit symbol and the valve can be avoided.

Pneumatic timer

The pneumatic timer can be precisely adjusted and is easy to read. Pressure changes do not alter the set delay time. Pneumatics at its best.

Optional Workbook

Nineteen project-orientated exercises, increasing in complexity and suitable for equipment set TP 101, are the ideal introduction to pneumatics. Real problem descriptions with positional sketch, concrete project tasks and detailed aids for professional implementation provide the ideal preparation for the real-life industrial environment.

This equipment set contains the following components:

- 2x 3/2-way valves with pushbutton, normally closed

- 1x 3/2-way valve with pushbutton, normally closed

- 1x 5/2-way valve with selector switch

- 1x 3/2- way valve with selector switch, normally closed

- 2x 3/2-way roller lever valve, normally closed

- 2x proximity sensors, pneumatic, with cylinder mounting

- 1x time delay valve, normally closed

- 1x pressure sequence valve

- 1x 3/2-way single-pilot valve

- 1x 5/2-way single-pilot valve

- 3x 5/2-way double-pilot valve

- 1x shuttle valve (OR)

- 2x dual pressure valve (AND)

- 1x quick-exhaust valve

- 2x one-way flow control valve

- 1x single-acting cylinder

- 1x double-acting cylinder

- 1x on/off valve with filter regulator

- 1x pressure regulator with pressure gauge

- 2x pressure gauges

- 1x distributor block

- 2x plastic tubing, 10 m, 4 x 0.75 mm

Topic Coverage

- Structure, function and application of single-acting and double-acting cylinders

- Calculating basic parameters

- Direct and indirect actuation

- Application and function of 3/2 and 5/2-way solenoid valves

- Analysing circuits

- Options for pressure measurement

- Pressure-dependent control systems

- Latching Circuits

- Logic operations: AND/OR/NOT

- Combining logic operations

- Function and application of limit switches

- End-position monitoring using electronic proximity sensors

- Time delay valves

- Realising oscillating movement

- Economic considerations of using pneumatic components

- Troubleshooting simple electropneumatic circuits

Additional equipment required to perform the exercises (Purchased separately)

| Qty | Description | |

|---|---|---|

| 1 | Compressor accessories | 8201523 |

| 1 | Rubber feet | 1583-4 |

| 1 | Aluminum profile plate 700 mm x 1100 mm | 1594-1 |

| 1 | Tubing cutter | 2558-5 |

| 1 | Compressor | 5654-4 |

Software

| Qty | Description | |

|---|---|---|

| 1 | FluidSIM 365 Pneumatics (1 year) | 81981-9 |

| 1 | FluidSIM 365 Pneumatic (3 years) | 81981-9 |

| 1 | FluidSIM 365 Pneumatics (5 years) | 81982 |