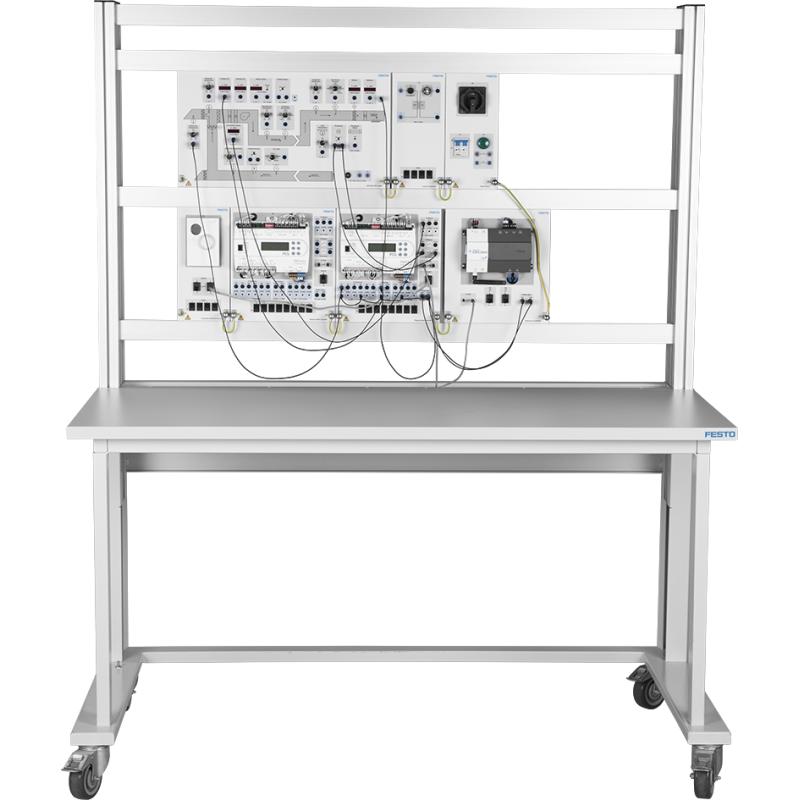

Teach the fundamentals of modern building HVAC controls in a compact system

This system teaches modern HVAC direct digital controls (DDC) of commercial buildings using components from Johnson Controls. Devices from the system communicate over an SA bus or FC bus using the widespread open source BACnet MS/TP protocol.

Building HVAC controls in the digital age

Most commercial buildings incorporate heating, ventilation, and air conditioning systems that are automatically controlled to ensure occupant comfort and health while minimizing energy consumption. Modern installations use a technology called direct digital control (DDC), a microprocessor-based system that can be programmed for various control sequences. These complex HVAC systems require installation and maintenance technicians to have a strong understanding of their general operation.

The Building HVAC Controls Learning System assists instructors in teaching the fundamentals of modern controls using commercially available components from Johnson Controls, a manufacturer recognized worldwide.

Simulated signals, real control

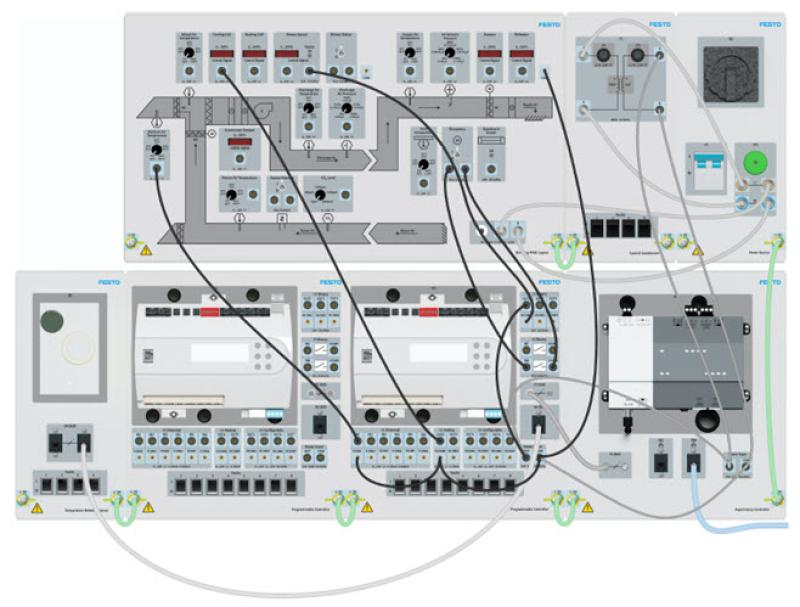

A module that represents a typical air handling unit (AHU) and simplified building ductwork makes it easy to change simulated temperature, pressure, humidity, and carbon dioxide levels, as well as occupancy. Actuators, such as dampers, cooling and heating stages, blower, and humidifier are also represented on the module. Simulated sensors and actuators are connected to a real field controller to demonstrate how a building HVAC control system responds to varying conditions. The field controller algorithm is optimized to reduce delays and save laboratory time.

Web-based monitoring

A human machine interface (HMI) accessible from any web browser through a Wi-Fi or a wired connection displays an on-screen representation of the building AHU and ductwork printed on the hardware module. Other advanced functions, such as scheduling, trending, and alarm management are also available.