PlantPAx™ Distributed Control System (DCS) Demonstrator - Pressure, Flow, Level, Temperature

3531-VGallery

Description

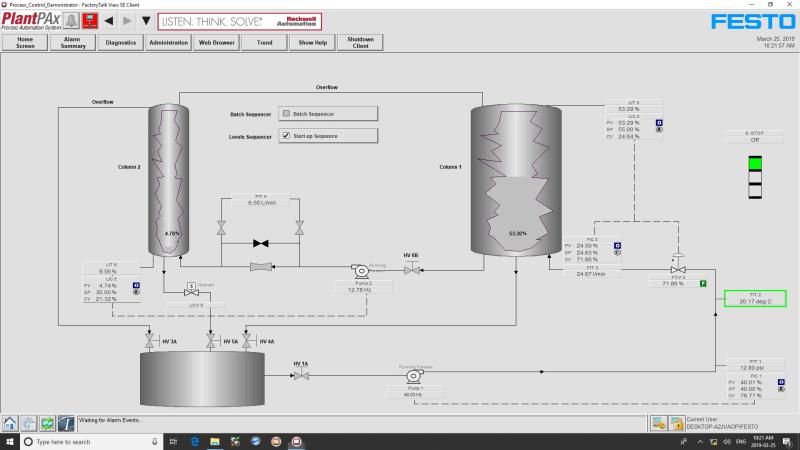

The Distributed Control System (DCS) Demonstrator is a modular demonstration unit capable of showing real-life process applications across a wide range of industries, including water and wastewater, oil refining, petrochemical, and food processing.

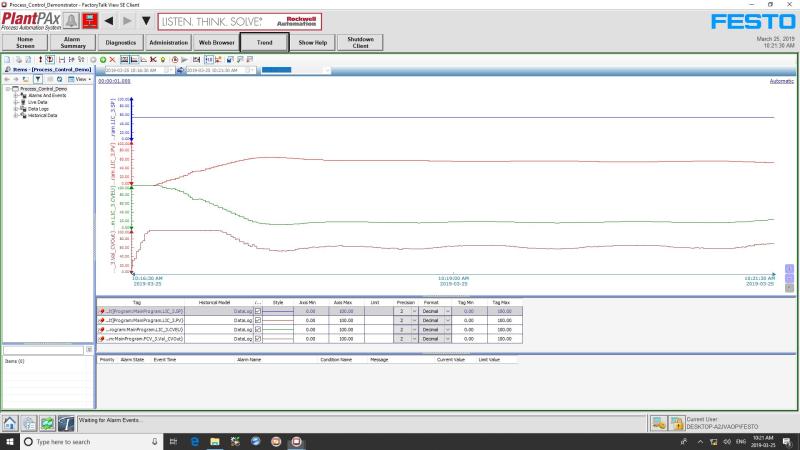

The PlantPAx DCS Training System is a demonstrator that can be used to train students on the instruments used to control or monitor industrial processes including temperature, pressure, flow, and level process variables. The training system is configured to teach different types of PID process control loops as well as different type of control strategies. The system is capable to monitor Pressure, Flow and Temperature process variables. The Demonstrator features two level PID control loops working simultaneously to maintain a stable level in each column even when disturbance occurs. The PID Level control loop of the large column works in Cascade mode with the flow rate and use a pneumatic control valve as a the final element.

The Demonstrator also features a pressure control loop that maintain a stable pressure at the inlet of the large column. The pressure control loop uses the centrifugal pump with an industrial variable frequency drive to maintain the desired pressure.

The Learning System uses modern equipment and user guides that will explain students on how to configure and use devices found in the process industry. The system also features a sequencer performing an automatic start-up sequence to facilitate the operation of the system.

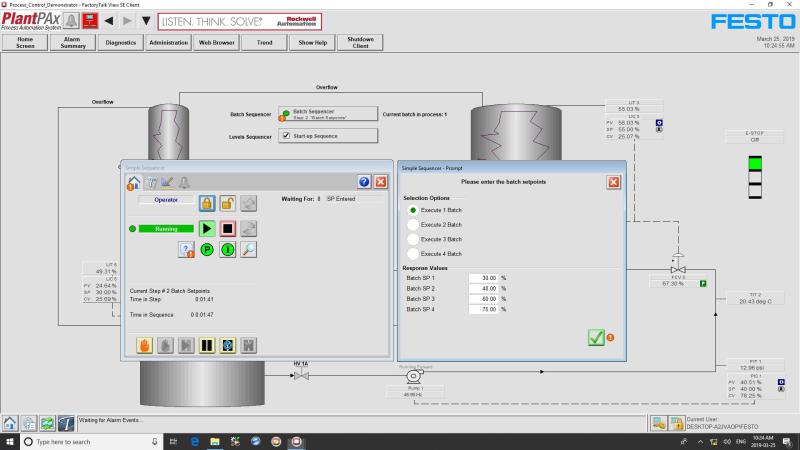

The Demonstrator features a batch sequencer that permit to fill-up the small column with four different amount of water and running the batches permit to the trainee to see the impact of the process stability.

Features & Benefits

- Smart transmitters using Hart, FOUNDATION Fieldbus, Profibus PA, Ethernet/IP communication protocols

- Many types of transmitters: Differential-pressure, Radar, Magnetic, Temperature

- Ethernet communication for variable frequency drives

- High-speed, touch screen computer

- Industrial Control Cabinet

- Advanced Network

List of equipment

| Qty | Description | Model Number |

|---|---|---|

| 1 | PlantPAx DCS Training System - Pressure, Flow, Level, Temperature | 46801-V |

| 1 | Electromagnetic Flow Meters (Workbook) | 85990 |

| 1 | Electromagnetic Flow Meters (Workbook (Instructor)) | 85990-1 |

| 1 | Control Valves (User Guide) | 86001-E |

| 1 | Radar Level Transmitters (Workbook) | 52200 |

| 1 | Radar Level Transmitters (Workbook (Instructor)) | 52200-1 |

| 1 | Familiarization with the Process Control Demonstrator (User Guide) | 52466-E |

Additional equipment required to perform the exercises (Purchased separately)

| Qty | Description | Model Number |

|---|---|---|

| 1 | Compressor | 6410-C |

| 1 | FactoryTalk View SE Station | 46968-5 |

| 1 | Calibration Kit | 46980 |

Software

| Qty | Description | Model Number |

|---|---|---|

| 1 | Studio 5000 Logix Designer Full Edition | 5935-1 |

| 1 | Studio 5000 Logix Designer Full Edition (Commercial) | 5935-B |

| 1 | FactoryTalk View Studio SE | 46968-4 |

| 1 | HART Software Configurator | 46982 |