Pressure, Flow, Level, and Temperature Process Learning Systems

3531Gallery

Description

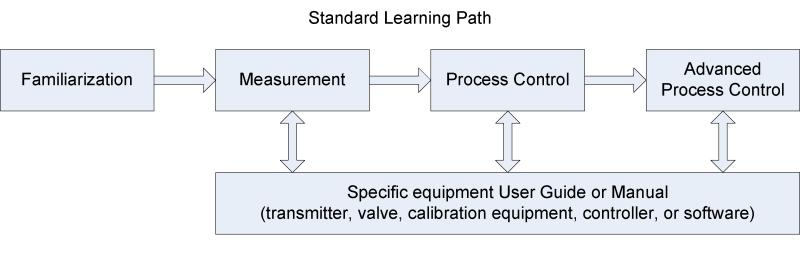

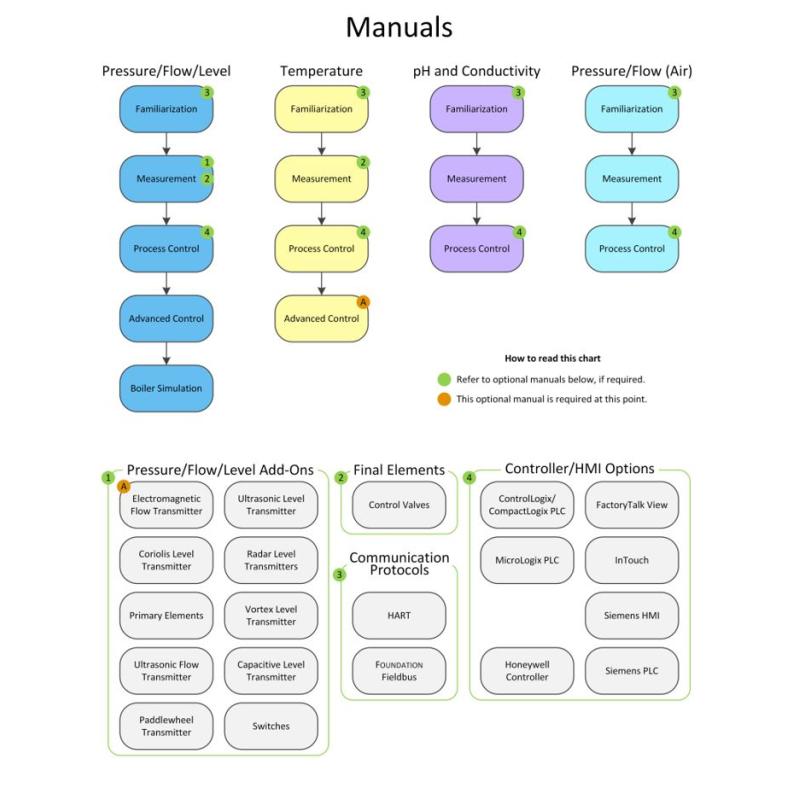

The Pressure, Flow, Level, and Temperature Process Learning Systems introduce students to a wide range of industrial processes, as well as to their instruments and control devices. The training systems are part of the Instrumentation and Process Control program, which uses modern equipment and a complete curriculum to help students assimilate the theoretical and practical knowledge that is mandatory to work in the process control industry.

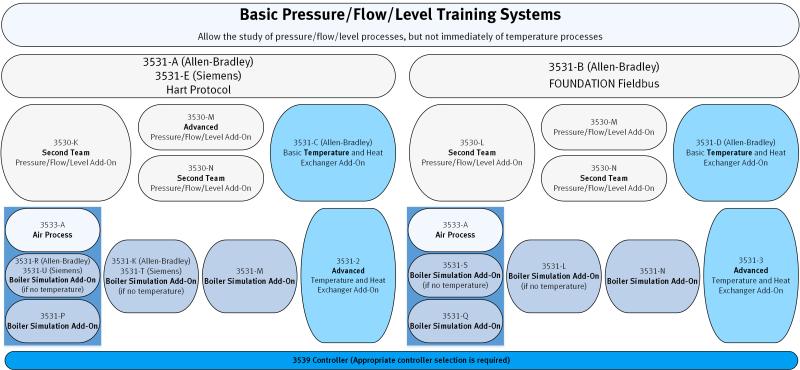

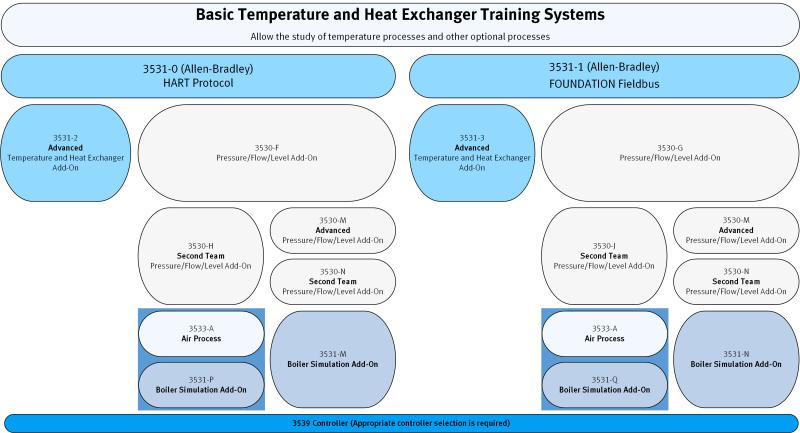

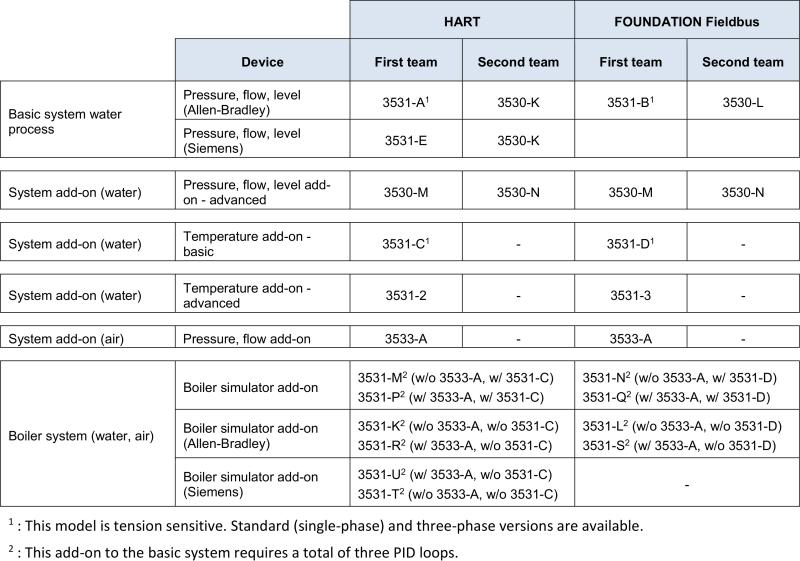

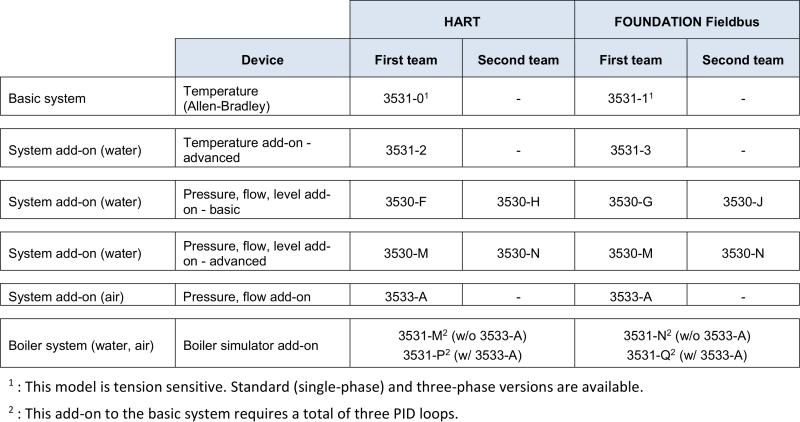

The modularity of these energy-efficient process control Learning Systems allows the instructor to select specific equipment as a function of the training objectives without going over budget. Several configurations are available for a single workstation. Adding optional equipment can increase the number of these configurations.

The Pressure, Flow, Level, and Temperature Process Learning Systems feature two workstations: the Process Workstation and the Instrumentation Workstation. The workstations can accommodate a single team of students for the temperature experiments and up to two teams for the pressure, flow, and level experiments if the second-team add-on is used.

The system also features training on complex control loop strategies such as the ones used for controlling a level in a boiler. For the boiler simulation, the students will need to apply different advanced control strategies such as split-range, ratio and feed-forward covered during the learning path adapted according to their specific needs.

Features & Benefits

- Modular system that allows a wide variety of configurations

- Two-sided workstation that enables two student groups to work simultaneously

- Faults can be inserted by the instructor to develop the troubleshooting skills of the students

- Extensive and comprehensive curriculum

- Entry level, cost-effective solution

- Industrial-grade components, clear PVC piping

- Real-world, large-scale process loops implemented in a space-efficient work environment

- Different controller options depending on the objectives and budget

- Smart transmitters and control valves implemented using HART or FOUNDATION Fieldbus communication protocols

- Ethernet and Modbus communication protocols also used with variable frequency drives and controllers

- Environment-friendly temperature training system (no cooling water required)

- Fast response temperature control system

- Advanced process control strategies such as ratio, feed-forward, and split-range

- Boiler simulation with three-element process control

- Real-time heat exchanger energy balance

Topic Coverage

- Temperature

- Pressure, Flow, and Level

- Air Pressure and Flow

- pH and Conductivity

- Estimated program duration: 84 hours

List of equipment

| Description | System Number |

|---|---|

| I/O Interface with LVProSim | 9065-B |

| Pressure, Flow, Level Process Add-On – HART | 3530-F |

| Pressure, Flow, Level Process, Second Team Add-On – HART | 3530-H |

| Pressure, Flow, Level, Second team add-on | 3530-K |

| Advanced Pressure, Flow, Level Process Add-On | 3530-M |

| Temperature Process Training System (Allen-Bradley) – HART | 3531 |

| Advanced Temperature Process Add-on – HART | 3531-2 |

| Pressure/Flow/Level Process Training System (Allen-Bradley) – HART | 3531-A |

| Temperature Process Add-On (Allen-Bradley) – HART | 3531-C |

| Pressure/Flow/Level Process Training System (Siemens) – HART | 3531-E |

| Boiler Simulation (Water/Air) Add-On (Allen-Bradley, Without Temperature Process) – HART | 3531-K |

| Boiler Simulation (Water/Air) Add-On – HART (needs the Temperature, and Advanced pressure, flow, level) | 3531-M |

| Boiler Simulation (Water/Air) Add-On - Siemens - HART (needs the Advanced pressure, flow, level) | 3531-T |

| Boiler Simulation (Water/Air) Add-On - Siemens - HART (needs the Air Process, and the Advanced Pressure, Flow, Level) | 3531-U |

| Air Pressure/Flow Process Add-On | 3533-A |

| ControlLogix PLC Bundle – Educational | 3539-5 |

| MicroLogix PLC Bundle – Educational | 3539-7 |

| CompactLogix PLC Bundle – Educational | 3539-8 |

| MicroLogix PLC Bundle – Commercial | 3539-C |

| CompactLogix PLC Bundle – Commercial | 3539-D |

| S7-1500 PLC Bundle HART – Educational | 3539-P |

| S7-1500 PLC Bundle – Educational | 3539-S |

Downloads

- Mining Industry Technology Brochure

- Measurement - Pressure, Flow, and Level - Courseware Sample (en)

- Advanced Process Control - Pressure, Flow, and Level - Courseware Sample (en)

- Process Control - Temperature - Courseware Sample (en)

- HART Device Configuration - Courseware Sample (en)

- FOUNDATION FieldbusTM Device Configuration - Courseware Sample (en)

- LabVolt Series - Brochure (en)

- Rockwell Automation - Solutions in Action - Festo Didactic

- Boiler Control - Courseware Sample (en)

- Process Control - Pressure, Flow, and Level - Courseware Sample (en)

- Measurement - Temperature - Courseware Sample (en)

- Heat Exchangers and Advanced Temperature Measurement - Courseware Sample (en)

- Oil, Gas, and Hydraulic Fracturing Technology Brochure

- Radar Level Transmitters - Courseware Sample (en)

- Building Tomorrow's Workforce - Innovative Technical Education Solutions - Brochure (en)