Process Control Training Systems

6090Gallery

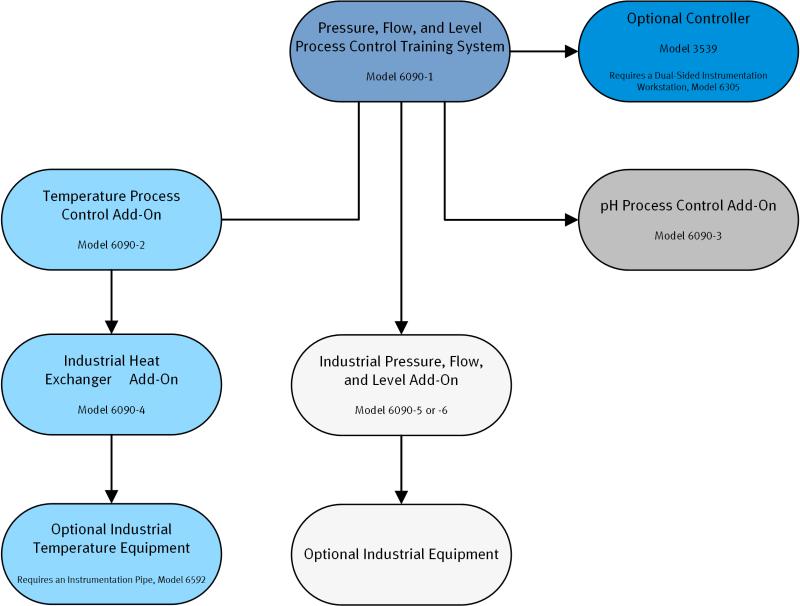

Structure of the Process Control Training System

Process Control Training System

Description

The Process Control Training Systems form a complete program designed to familiarize students with the fundamentals of instrumentation and process control. It demonstrates the control of pressure, flow, level, temperature, and pH processes. It can also demonstrate advanced process control techniques, such as feed-forward control, second-order control, and cascade control when used with a controller featuring these functions.

Features & Benefits

- Equipment

- Many work surface, bench, and panel options

- Stainless-steel drip tray

- Cost-effective solution when compared to industrial training systems

- Bench offers lockable storage

- Wide range of add-ons and optional components to expand learning

- Moveable components build a foundation of knowledge one device at a time, making it easier to teach circuit assembly

- Create circuits to mimic industry-specific process control applications

- Fault switches on most of the industrial components enable real-world troubleshooting

- HART or FOUNDATION Fieldbus communication protocols

- Environmentally friendly temperature training system (no cooling water required)

- Curriculum

- Process control simulation software available

- Curriculum available in job-sheet format in standard student activity manuals or in PDF format on CD-ROM as a site license

- Innovative approach that also allows interconnection with other products, such as pneumatics applications, PLCs, etc.

Topic Coverage

- Pressure, Flow and Level Processes

- PID Controller and Process Control

- Temperature Processes and Measurement

- pH Control and Measurement

- Process Dynamics

- Proportional Plus Integral/Derivative Control Mode

- Estimated total program duration: 110 hours

List of equipment

| Description | System Number |

|---|---|

| Pressure, Flow, and Level Process Control Training System | 6090-1 |

| Temperature Process Control Add-On | 6090-2 |

| pH Process Control Add-On | 6090-3 |

| Industrial Heat Exchanger Add-On | 6090-4 |

| Industrial Pressure, Flow, and Level Add-On - HART | 6090-5 |

| Pressure, Flow, and Level Process Control Training System (Entry-Level Solution) | 6090-8 |

| Pressure, Flow, Level, and Temperature Process Control Training System (Entry-Level Solution) | 6090-9 |

| Pressure, Flow, and Level Process Control Training System (with Bench and Panels) | 6090-B |

Additional equipment required to perform the exercises (Purchased separately)

| Qty | Description | System Number |

|---|---|---|

| 1 | Personal Computer | 8990 |

| 1 | Antibacterial Solution | 38097 |

| 1 | Touch-Screen Computer – Large | 46299-A |